Budget-friendly and Reliable Industrial Scales for each Service

Budget-friendly and Reliable Industrial Scales for each Service

Blog Article

Exactly How Commercial Scales Improve Accuracy in Production and Logistics

By ensuring that products are considered accurately, organizations can alleviate mistakes that can lead to substantial economic repercussions. The development of sophisticated technologies in considering systems is changing typical procedures.

Significance of Precision in Procedures

In the world of manufacturing and logistics, accuracy is the foundation of operational performance. Exact dimensions are necessary for preserving quality assurance, optimizing source appropriation, and making certain conformity with industry criteria. When procedures depend on accurate data, businesses can lessen waste, enhance production timelines, and enhance total performance.

The relevance of precision prolongs beyond easy dimension; it also affects decision-making processes. For example, precise weight readings can establish proper stock levels, streamline supply chain logistics, and facilitate exact invoicing. In addition, mistakes in measurements can cause costly mistakes, such as overproduction or taking too lightly product demands, which can threaten project timelines and earnings.

By carrying out rigorous dimension requirements, companies can identify ineffectiveness and pass improvements, inevitably leading to improved customer fulfillment. Thus, investing in accuracy measurement tools, such as industrial ranges, is not merely a technical consideration but a strategic necessary for success in the manufacturing and logistics fields.

Sorts Of Industrial Scales

Numerous types of commercial ranges play a crucial function in attaining the precision necessary for effective production and logistics procedures. Each kind is made to meet details needs, making sure accurate measurement of elements, items, and materials.

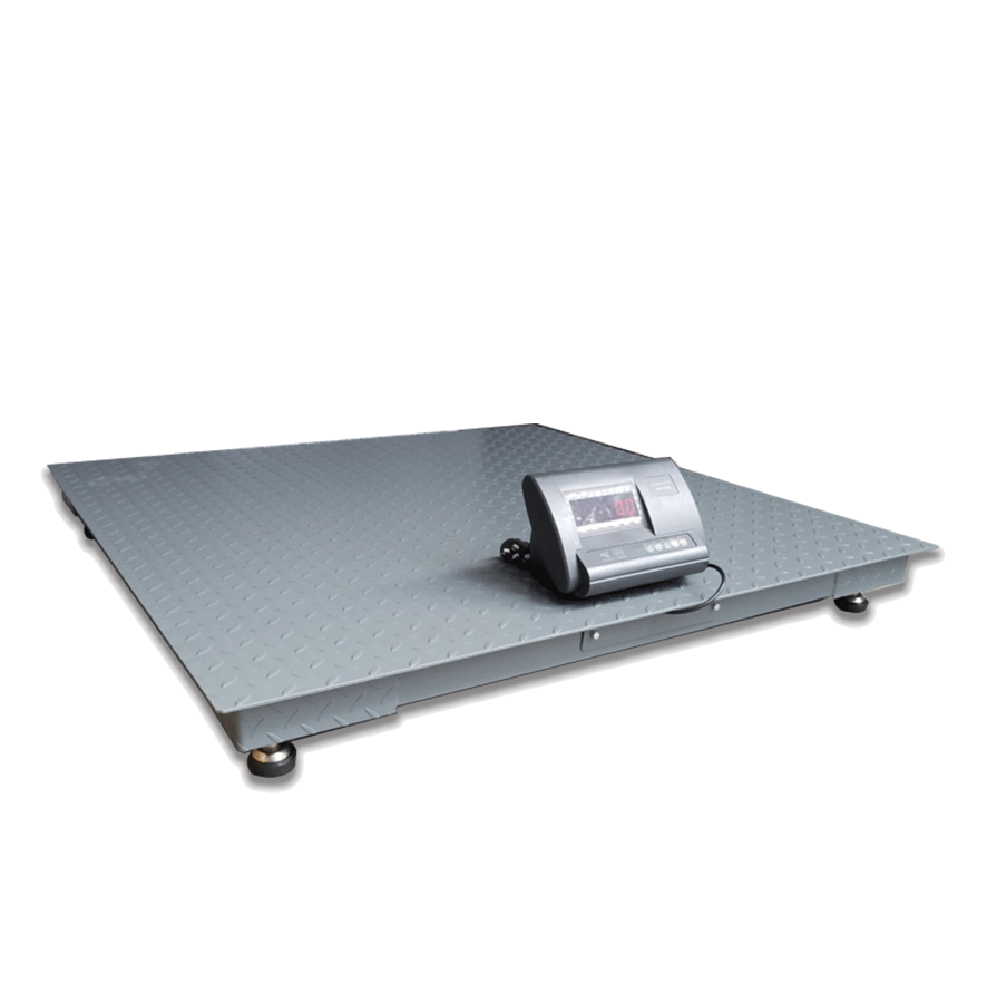

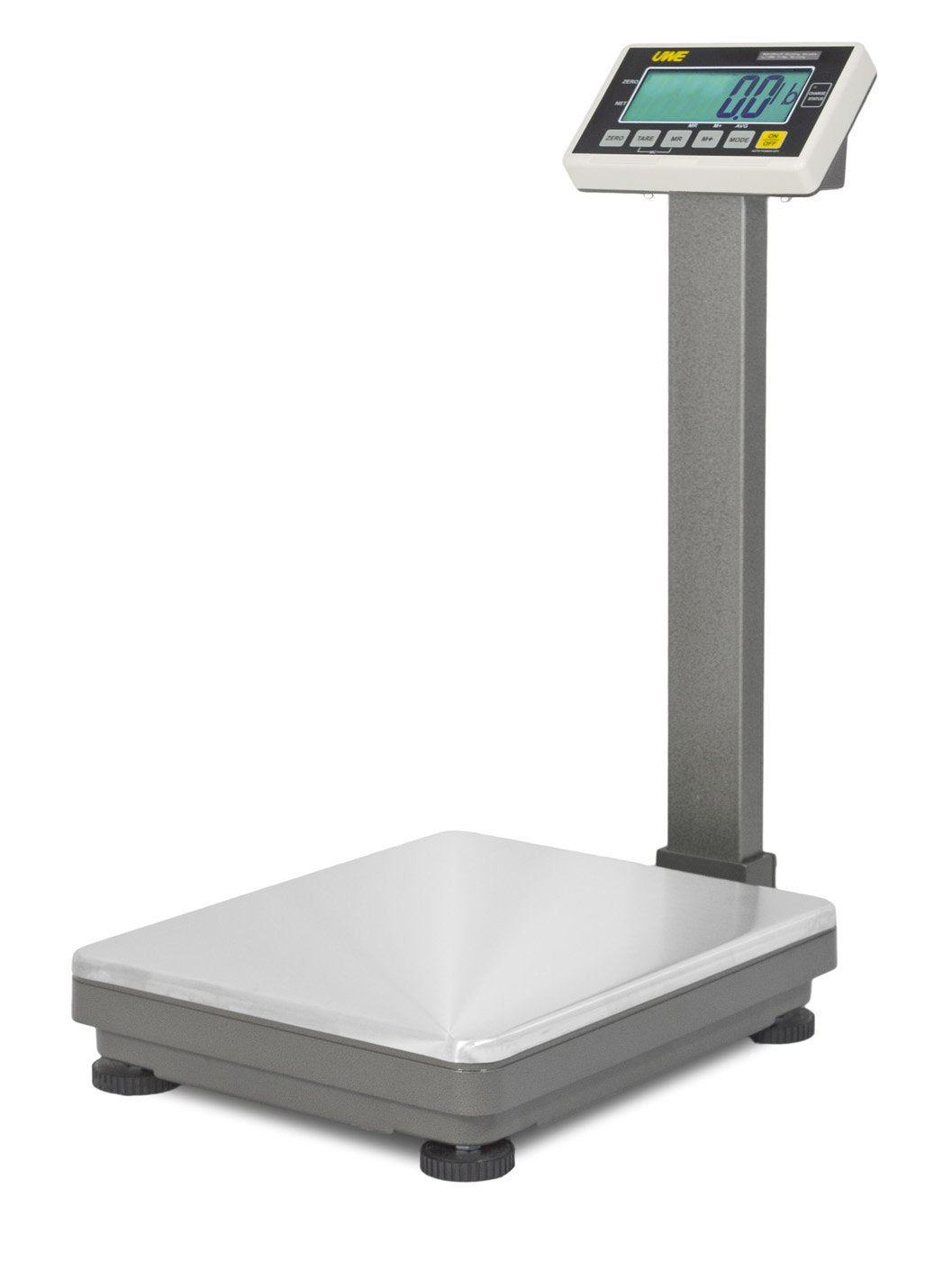

One usual type is the system scale, which provides a level surface for weighing bulk materials or huge products. These scales are typically utilized in storage facilities and shipping facilities. Another kind is the bench range, commonly smaller and used for evaluating individual packages or smaller sets of products. These ranges are crucial in quality assurance processes. Industrial Scales.

For applications where accuracy is crucial, logical balances are employed. These high-accuracy scales are utilized in laboratories and research study setups to measure tiny quantities with utmost precision. Floor ranges, made for sturdy evaluating, are perfect for weighing big pallets or containers, usually integrated with forklifts for efficiency.

On top of that, tons cells are used in different applications for real-time weight measurement and data collection. Each of these ranges contributes distinctively to the operational efficiency, making certain that businesses can maintain accuracy throughout their manufacturing and logistics processes. Comprehending the sorts of commercial ranges is vital for enhancing efficiency and attaining functional quality.

Effect on Supply Monitoring

Precise evaluating is important for effective inventory monitoring, as it directly affects supply precision and operational performance. In manufacturing and logistics, accurate dimension of items and materials makes sure that inventory records show real stock levels, decreasing inconsistencies that can lead to overstocking or stockouts. Industrial ranges supply the essential precision to consider things properly, check making it possible for companies to keep a reliable inventory system.

In addition, precise evaluating adds to better projecting and preparation. With specific information on supply degrees, companies can make enlightened choices pertaining to procurement and manufacturing schedules. This decreases the risk of excess inventory, which can lock up funding and rise storage space costs, as well as avoid shortages that may interfere with operations.

Furthermore, the combination of industrial ranges with stock monitoring systems assists in real-time monitoring of supply movements. This improves the process of updating supply records, enhancing openness and responsibility throughout the supply chain. Inevitably, precise weighing not just supports reliable inventory monitoring however also drives total functional efficiency, making it possible for services to react swiftly to market needs and preserve an one-upmanship in their particular sectors.

Enhancing Quality Assurance

Effective stock administration not just guarantees optimum supply levels but additionally lays the groundwork for durable high quality control processes. Industrial ranges play a pivotal role in improving quality control by offering precise weight measurements that are crucial for maintaining product integrity. Constant weight confirmation enables makers to stick to requirements, making sure that each item satisfies the needed quality requirements.

In high-stakes settings, such as food manufacturing or pharmaceuticals, even small weight disparities can cause significant conformity problems. By integrating industrial ranges right into the assembly line, companies can keep an eye on product weights in genuine time, enabling immediate restorative activities if problems are spotted. This positive technique decreases waste and enhances overall product dependability.

In addition, accurate weighing assists in far better formulation Resources of raw materials, which is vital in industries like cosmetics and chemicals. By making certain that component proportions remain consistent, suppliers can accomplish premium product high quality, improving customer satisfaction and reducing returns.

Future Trends in Weighing Innovation

The future of evaluating modern technology is poised for substantial advancements driven by automation, connectivity, and information analytics. As markets develop, the assimilation of innovative sensors and IoT (Internet of Things) capabilities will enable real-time monitoring and reporting of weight information. This connection will not only enhance functional effectiveness however also promote anticipating maintenance, reducing downtime and boosting efficiency.

Additionally, the incorporation of expert system and artificial intelligence algorithms right into evaluating systems will certainly improve data evaluation abilities. These technologies can determine patterns and anomalies, enabling more informed decision-making and More Help maximized supply chain administration. The surge of cloud-based options will certainly make it possible for seamless data sharing throughout systems, making sure that stakeholders have accessibility to updated info at all times.

Sustainability will also play a crucial duty in future evaluating modern technology. As services make every effort to lessen their carbon footprint, evaluating systems that incorporate energy-efficient layouts and materials will certainly become significantly vital. Additionally, advancements in digital considering scales will sustain much better source management by providing accurate measurements that lower waste.

Verdict

To conclude, commercial ranges considerably boost precision in production and logistics by providing accurate weight measurements crucial for reliable procedures. Their duty in supply monitoring, top quality control, and assimilation with innovative innovations highlights their value in maximizing and lessening inconsistencies source allowance. As markets continue to develop, the adoption of ingenious evaluating services will further support functional performance and reduce waste, ultimately adding to improved productivity and competitiveness on the market.

One typical type is the platform scale, which offers a level surface area for considering big products or bulk materials. One more type is the bench range, normally smaller and used for considering individual plans or smaller sets of products. Floor ranges, developed for sturdy evaluating, are ideal for considering large pallets or containers, often incorporated with forklifts for efficiency.

Industrial ranges offer the essential precision to weigh products accurately, making it possible for services to keep a dependable supply system.

Report this page